Antibacterial

DEFLECTA ANTIBACTERIAL® is a clear biocide formulation with bacterial control properties which produces a sanitised surface, on and within the concrete matrix.

Used for

Industry

Can be applied to both interior or exterior concrete slabs in areas such as food and beverage, pharmaceutical, health, agricultural, dairy, animal husbandry, manufacturing/ processing, education and sporting facilities.

Buyers

Architects, Builders, Contractors, Applicators, Clients, International.

Materials

Concrete/cementitious based materials.

About Antibacterial

Description

DEFLECTA ANTIBACTERIAL® is Government Certified (APVMA approval no. 83823/109029) and Registered Biocide treatment for concrete. It impregnates both new and aged concrete with a biocide treatment that kills 99.99% of bacteria/pathogens such as; Golden Staph, E-coli, Listeria and Salmonella, on and within the concrete matrix for a minimum of 5 years. DEFLECTA ANTIBACTERIAL® is safe to use near humans and animals.

How it works

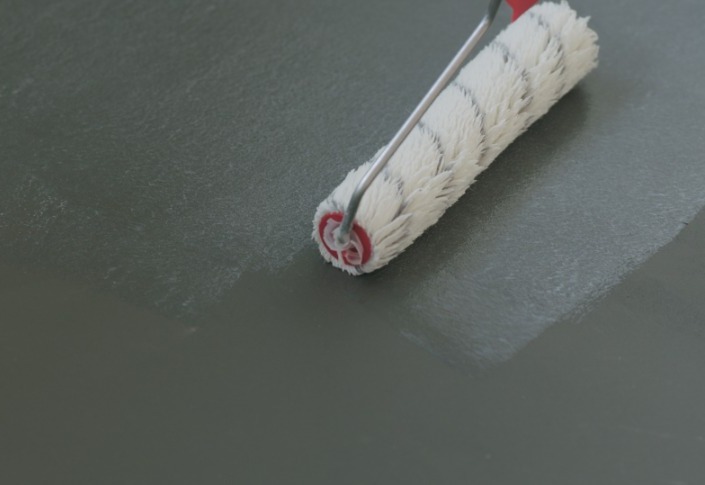

DEFLECTA ANTIBACTERIAL® treatments when applied to the concrete surface both penetrates and sanitizes the concrete and the biocide becomes active killing bacteria @ 99.99%. The treatment remains active for a period of 5 years.

Benefits

- Kills disease carrying bacteria on concrete including; Staphylococcus aureus (Golden Staph) - Listeria - Escherichia coli (E.coli) - Salmonella

- Active at 99.99% up to a depth of 100mm into the concrete matrix for minimum period of 5 years

- Suppresses growth of mould, mildew and fungi

- Purges waste material and odours i.e. urine, oil etc., from aged concrete while sanitising it's matrix and surface

- Excellent pre-treatment for topical coatings

- VOC* Low < 10 grams per litre Green Star Design, Green Star Building Compliant

- VOS* Zero

- Water based and non-toxic formulation

- Approved by HACCP International for use in food preparation areas

- Bio-degradable

- Allows necessary vapour transmission

- Excellent pre-treatment for topical coatings

*VOC/VOS = Volatile Organic Compounds and Volatile Organic Solvents

DOWNLOADABLE RESOURCES

Technical Information

Related Case Studies

Aldi Car Park

DEFLECTA STABILIZER® and DEFLECTA TOPEL® was applied to the Truck Loading Ramp and walkways, this assisted t...

Aldi

Commercial

Related Case Studies

Aldi Food Stores (Australia Wide)

DEFLECTA® products are specified to ALDI Food Stores back of house food packaging, Freezer and Chiller rooms....

Aldi

Commercial

Related Case Studies

Australian Synchrotron

DEFLECTA ANTIMICROBIAL® followed by DEFLECTA SURFACE BINDER® was applied to the underground carpark at the A...

Australian Synchrotron

Commercial

Related Case Studies

Box Hill Hospital Development

DEFLECTA ANTIMICROBIAL® was applied to all carpeted and viny areas with its key responsibility to prevent bac...

Box Hill Hospital

Commercial

Related Case Studies

Coles Hamilton

DEFLECTA STABILIZER® was applied to all front of house food retail areas including the liquor section at time...

Coles

Commercial

Related Case Studies

Kawana Waters - Car Park

DEFLECTA TOPEL® was applied to the Kawana Waters multi-level car park complex, ground, mezzanine, roof top an...

Kawana Waters

Commercial

Related Case Studies

Docklands Carpark, Melbourne

DEFLECTA ANTIMICROBIAL® and DEFLECTA SURFACE BINDER® was applied to the Docklands Carpark concrete surface...

Docklands Carpark

Commercial

Related Case Studies

EKKA - The Royal Queensland Show

DEFLECTA ANTIMICROBIAL® was applied to 'The EKKA' complex car park concrete floor and columns, ground to leve...

EKKA

Commercial

Related Case Studies

Essendon Fields - Car Park & Office Area

DEFLECTA TOPEL® and DEFLECTA MOISTURE SUPPRESSANT® products were applied to the Car Park and Office Area at ...

Essendon Fields

Commercial

Related Case Studies

Mansfield Public Toilet Block

DEFLECTA ANTIMICROBIAL® and DEFLECTA BOTANY® was applied to the restoration work project, carried out by the...

Mansfield

Commercial

Related Case Studies

Penleigh and Essendon Grammar School

DEFLECTA TOPEL® was applied to exposed concrete walkways and paving areas to maintain the surface wearability...

Penleigh

Commercial

Related Case Studies

Victorian Dairy Processor

DEFLECTA ANTIMICROBIAL® was applied to the new warehouse facility to reduce the risk of bacterial outbreaks w...

VDP

Commercial

Related Case Studies

Fresh Plus

DEFLECTA TOP COAT®, DEFLECTA ANTIMICROBIAL® and DEFLETA SUFACE BINDER® were all applied to new fit out Supe...

Fresh Plus

Commercial

Contact

Get a free no

obligation quote

We understand that choosing the correct solution and type of product is essential for the success of any project. Deflecta has a technical support team with many years of concrete industry experience and successful project applications and are ready to help you find the right solution for your application.

Products

You may also like

RELATED FAQs

Frequently Asked Questions

-

Can DEFLECTA ANTIBACTERIAL® help to stop the mould?

The product will reduce the occurrence of mould

-

Can DEFLECTA ANTIBACTERIAL® help to stop efflorescence?

The product will reduce the occurrence of efflorescence.

-

How does Can DEFLECTA ANTIBACTERIAL® purge the waste materials and odours from the concrete matrix to the surface?

The product activates within the concrete matrix to kill bacteria which releases and purges contaminants/waste material and odours through to the surface.

-

Can DEFLECTA ANTIBACTERIAL® kill bacteria?

Yes. The product is designed to kill bacteria and stay active both within and on the surface of the concrete.

-

Is this product Green Star compliant?

Yes. The product is compliant with Green Star Building Council of Australia.

-

How long before topical finishes/coatings can be applied on DEFLECTA ANTIBACTERIAL®?

If DEFLECTA ANTIBACTERIAL® was applied to aged concrete greater than 28 days from time of pour, you must wait 24 to 72 hours.

-

Can all the DEFLECTA® products be applied to aged concrete?

Yes. All the DEFLECTA® products can be applied to aged concrete (any time after 28 days from time of pour).

-

Can all the DEFLECTA® products be applied to new concrete?

No. Only DEFLECTA ANTIMICROBIAL®, DEFLECTA STABILIZER® and DEFLECTA® COOPER CONTROLTM can be applied to new concrete (at the time of pour).

-

Why do you broom the product around the floor area?

To allow the product to be evenly spread out and to prevent pooling.

-

What are the consequences if the surface area to be treated is not cleaned properly before the application?

Possible product performance failure.

-

What does the DEFLECTA ANTIBACTERIAL® do?

The product kills bacteria within and on the concrete surface.

-

Why does the surface need to be clean before you apply your products?

To allow the product to penetrate or seal correctly a clean, dust free surface is required

-

How long until DEFLECTA ANTIMICROBIAL® is required for another application, when applied under topical floor finishes?

Generally, when floor finishes are replaced you can re-apply DEFLECTA ANTIMICROBIAL®. If there is no moisture concern, DEFLECTA ANTIBACTERIAL® can be applied.

-

Where can we apply DEFLECTA ANTIBACTERIAL®?

You can apply DEFLECTA ANTIBACTERIAL® to any cementitious/ concrete floor or render/ putty wall and ceiling to control bacteria and odours.

-

What should I do if the product gets onto glass etc?

Immediately remove the product with soapy water to avoid the product etching the glass.

-

Can anyone apply the product?

Yes. Although training and certification is required to apply the products on commercial projects.

-

Can the DEFLECTA® products be used internally and externally?

DEFLECTA SURFACE BINDER®, DEFLECTA MOISTURE SUPPRESSANT® and DEFLECTA HEALTH SEAL® are manufactured for internal surface applications, all other products can be applied to internal or external surface areas.

-

How long until DEFLECTA ANTIBACTERIAL® is required for another application on exposed concrete?

DEFLECTA DEFLECTA ANTIBACTERIAL® has an Australian Government registration for bacteria control. Testing is recommended after 5 years to verify if the biocide is still active.

-

Does DEFLECTA ANTIBACTERIAL® affect the adhesion under floor coverings?

No. As the products leaves a key at the surface, this allow moisture to dissipate. The surface will require a progress sand or light grind to remove any purged materials.

Read more